I collected knives and swords for years as a kid, running around in the woods with cheap flea market junk, hacking up all of the bushes and branches in my way. The most expensive thing I owned was a $30 sword with a bright blue handle, every kid’s wildest dream. That was, until I saw a knife for $80, which utterly blew my mind that a knife could be that expensive. Then, a question arose that began this journey into knife making:What makes a knife $8 vs $80?

In trying to figure out the answer, I began to study how knives were made. I learned that materials matter, processes matter. Geometry, ergonomics, heat treatment, fit and finish; all new concepts that were each their own rabbit hole to dive down. Of course, that ended up leading to a YouTube video showing how to make a knife in your backyard out of a file. All it took was one ugly knife-shaped-object and a week of lost time, and I was absolutely hooked.After years of backyard bladesmithing, I went to university for mechanical engineering. As great as it was, most of the time that should’ve been spent learning fluid mechanics and structural dynamics was instead devoted to metallurgy, forging processes, and (along with a new found love of cooking) the intricacies of kitchen knives. There was a depth in kitchen knives that other types of cutlery simply didn’t have. With a fresh mechanical engineering degree, I ventured out to Oregon to make knives full time in 2016. After a three year grind of making knives, I was lucky to be invited to participate on the show Forged in Fire, and the prize money gave me the opportunity to open my own shop in Feb. 2020.Working in my own shop has allowed me to explore and expand my personal style, where I focus on turning simple, functional lines into something beautiful and unique. My primary skill set is in hand forged high carbon steel and laminating my own san-mai and damascus patterns in house. I exclusively make kitchen knives, and seek to make tools for chefs and home cooks that will be a joy to use for years to come.Alex Horn Knives

Browse by tag:

Alex Horn 245mm Suminigashi Gyuto

Alex Horn 245mm Suminigashi Gyuto

$1,350.00

Steel: 52100 core with nickel and mild steel Suminigashi cladding, hand forged and laminated in shop HRC: 62 Construction: Sanmai Damascus Length: 245x53mm 2.70mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Ice camo carbon fiber w/ pewter g-10 liners and black linen micarta frame

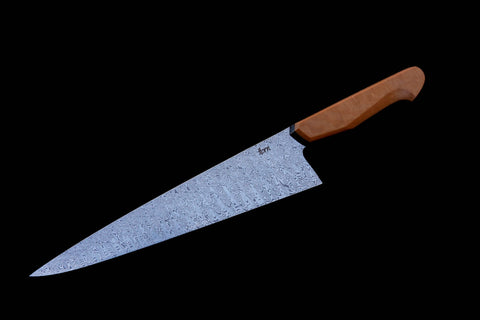

Alex Horn 225mm Laddered W's Gyuto

Alex Horn 225mm Laddered W's Gyuto

$1,250.00

Steel: 26c3 &15n20 HRC: 63 Construction: Laddered W Damascus Length: 225x50mm 2.60mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Buckeye burl handle w/ blue and black g-10 liners and black linen micarta frame

Alex Horn 180mm Damasteel Gyuto

Alex Horn 180mm Damasteel Gyuto

$1,000.00

Steel: Damasteel (Stainless Damascus) HRC: 63 Construction: Damascus Bi Frost Pattern Length: 180x44mm 2.77mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Redwood Burl with Micarta Cap and G10 Spacers

Alex Horn 230mm Damasteel Gyuto #3

Alex Horn 230mm Damasteel Gyuto #3

$1,500.00

Steel: Damasteel (Stainless Damascus) HRC: 63 Construction: Damascus Bi Frost Pattern Length: 232x52mm 2.76mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Wenge with Micarta Spacer and Koa Bolster

Alex Horn 235mm Damasteel Gyuto #2

Alex Horn 235mm Damasteel Gyuto #2

$1,500.00

Steel: Damasteel (Stainless Damascus) HRC: 63 Construction: Damascus Bi Frost Pattern Length: 235x52mm 2.65mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Natural Buckeye Highly Compressed with G10 Liners

Alex Horn 235mm Damasteel Gyuto

Alex Horn 235mm Damasteel Gyuto

$1,500.00

Steel: Damasteel (Stainless Damascus) HRC: 63 Construction: Damascus Odin Heim Pattern Length: 235x51mm 2.62mm Spine at Heel Finish: Etched Blacksmith: Alex Horn Handle: Warm Micarta with Carbon Fiber Liners